The Desk SEM Coater model DSR1 is a compact coating system able to coat noble metals such as gold (Au), palladium (Pd), platinum (Pt) and gold/palladium (Au/Pd) thin films on non-conductive or poorly conductive specimens.

The DTT is a desk top, turbo molecular-pumped thermal evaporator for vacuum deposition of thin films. The triple-source evaporation with evaporation source (boat / basket / coil) selection system is ideal for deposition of multilayer or alloys.

The DST3-T is a triple-target, turbo molecular-pumped, multi vacuum coater system, combines thermal evaporator and sputter coater in one single compact desktop system. It is suitable for deposition of a wide range of materials. The system can easily…

The DST3 is a desk top, triple target, turbo molecular vacuum pumped sputter coater, suitable for sputtering semiconductors, dielectrics, metals and metal oxides. The DST3 is equipped with a large chamber (300 mm diameter) and three 2” diameter…

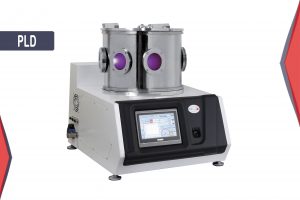

PLD – T is a high vacuum thin film deposition system enables to deposit different materials by both Pulsed Laser Deposition and so thermal evaporation technique. It can deposit complex materials and crystalline structures onto substrates with very little setup involved.

Desk Carbon Coater is a compact carbon fiber coating system suitable for sample preparation for the use in scanning electron microscope (SEM), Transmission electron microscope (TEM) and X-Ray analysis (EDX). The Desk vacuum carbon coater is able to perform…

The magnetron desk sputter coater model DST1-300 is a coating system with ability to coat semiconductors, dielectrics and metals (oxidizing and non-oxidizing). Uniform thin films with fine-grain sizes are formed in a fast cycle time.

The Desk SEM Coater model DSCR is a compact coating system included both of sputter and so carbon coater. This system is able to sputter noble metals such as gold, palladium, platinum and gold/palladium on non-conductive or poorly conductive specimens…

The magnetron desk sputter coater model DST1-170 is a compact coating system with ability to coat metals (oxidizing and non-oxidizing). Uniform thin films with fine-grain sizes are formed in a fast cycle time. The DST1-170 is equipped with…

The large chamber rotary pumped DSCR-300, Desk Sputter & Carbon Coater, is a compact coating system for both sputter and carbon coating. This system is suitable for non-oxidizing targets deposition on large specimens.

DCT is a turbo-pumped carbon coater that is ideal for FE-SEM, EDS/WDS, TEM, EBSD and thin film applications. This high vacuum coater offers high quality uniform carbon films with fine grain sizes which are suitable for specimens that require high resolution

The DSCT is configured as a sputter coater and fiber carbon coater with interchangeable heads in one instrument suitable for Scanning Electron Microscope (SEM) sample preparation. This high vacuum coater offers high quality uniform films

The Sputter Coater and Carbon/Thermal Evaporator – DSCT-T is configured as a sputter coater, carbon coater, and thermal evaporator with three interchangeable heads in one instrument suitable for Scanning Electron Microscope sample preparation.

VCS100F is sputtering system and thermal evaporation platform with turbo molecular pump for high vacuum. This system is equipped with two magnetron cathode with 3 degrees of freedom adjustment, DC power supply, RF power supply with matching box and…

| Options & Features | DSR1 | DSCR | DSCR-300 | DCR | DST1-170 | DST1-300 | DSCT | DSCT-T | DCT | DST3-A | DST3-S | DST3-TA | DST3-TS | DST2-TG | DTE | DTT | PLD | PLD-T |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sputtering | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| Carbon Evaporation | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||||||||

| Resistance Thermal Evaporation | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||||||||

| Pulsed Laser Deposition | ✔ | ✔ | ||||||||||||||||

| Multi Layer Deposition | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |||||||||

| Co-Sputtering or Co-Evaporation | ✔ | ✔ | ✔ | ✔ | ||||||||||||||

| RF Power Supply | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||||||||

| High Voltage DC Power Supply | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||

| High Current Power | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||||||||

| Rotary Pump | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| Turbo Pump | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | ||||

| *Size of Vacuum Chamber | S | S | L | S | S | L | S | S | S | L | L | L | L | L | S | L | L | L |

| Number of Targets or Thermal Sources | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 3 | 3 | 3 | 3 | 3 | 1 | 3 | 3 | 3 |