In 1402, Nanostructured Coatings Company has widely exported nearly 70 of its vacuum coating products, working based on physical vapor deposition method, to various countries.

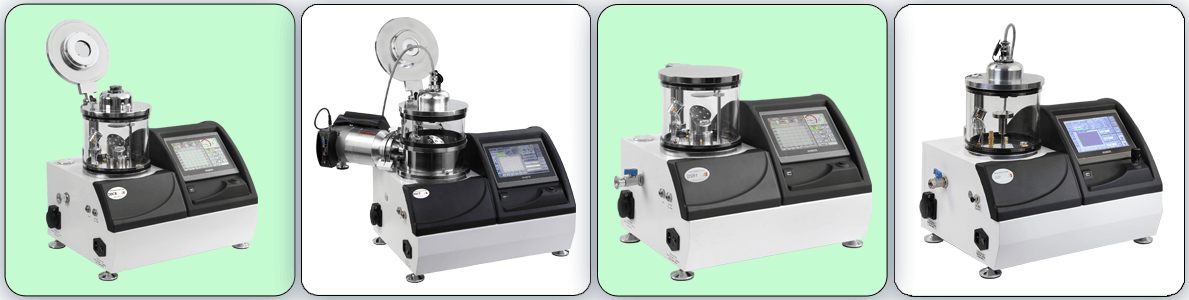

Vacuum coating devices produced by NSC Company use various coating methods, such as sputtering, thermal evaporation, and pulsed laser deposition (PLD) to create a thin film on the substrate. The sputter coaters, carbon coaters, thermal evaporators, and pulsed laser deposition systems of this company are widely used for the sample preparation for electron microscopy and research projects.

NanoStructured Coatings Co.’s combined sputter and carbon coaters, models DSCR and DSCT, which are primarily used to deposit a thin layer of a conductive material, such as metal or carbon, onto an electron microscope specimen, have been among the best-selling coaters in 1402. Also, DSR1 low vacuum sputter coater and DCR low vacuum carbon coater are among the favorite SEM coaters of the company. The DST3 large triple-target coating machine and the DST2-TG for glove box are also among the company’s export products, which are convenient deposition systems for multi-layer deposition and alloying.

The NSC products are offered in various models and can be customized based on customer needs along with various optional features such as RF sputtering, substrate bias voltage, glow discharge (Plasma rod), substrate heater, etc. These devices, depending on the selected model, can be used to prepare SEM samples, apply plasma on the surface of the samples, or grow multiple layers or alloy.

The advanced products of the NSC Company have been welcomed in universities and research centers in different countries, including England, Germany, Italy, Spain, Portugal, South Korea, China, Egypt, Australia, Czech Republic and India.