IUST Researchers Utilized NSC Triple-Cathode Sputter Coater, DST3-A, in Deposition of Antibacterial Ti-Cu Layers

The researchers at the Physics Department of Iran University of Science and Technology (IUST) achieved a Ti-Cu layer with antibacterial properties through the co-sputtering of Ti and Cu with DST3-A magnetron sputter coater manufactured by NanoStructured Coating Company (NSC). The significant results of this research are published in the Scientific Reports journal of Nature publications.

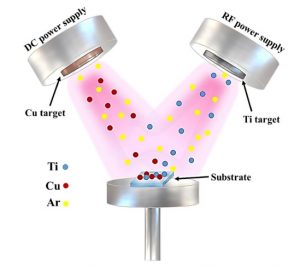

The results of this research have shown the highest antibacterial ability against E. coli and S. aureus bacterial strains for the Ti14-Cu86 layer composition. The Ti layer was deposited on the glass and silicon substrates by applying RF voltage, while a DC power source was used to sputter the Cu target. Both targets were submitted to a 5-minute pre-sputtering process to remove the contaminants.

The samples were characterized by the SEM and AFM techniques to analyze their surface structures. The wettability of the structures is another verification parameter for the layer’s antibacterial property, the more hydrophobic layer shows better antibacterial behavior.

NanoStructured Coatings Company is a globally renowned designer and manufacturer of vacuum coating systems, offering versatile coating systems based on the physical vapor deposition (PVD) method for research and SEM sample preparation. Low and high-vacuum coating sputter coaters, carbon coaters, and hybrid sputter/carbon coaters are the most favorite NSC coating systems among users.

The angled triple-cathode desk sputter coater, DST3-A, is a powerful tool to perform state-of-the-art research projects where co-sputtering is required, whereas the straight triple-cathode sputter coater, DST3-S is ideal for consecutive uniform coating on larger (up to 8-inches) substrates.