The DST3 is a triple-target, turbo molecular-pumped, vacuum coating system. It is suitable for deposition of a wide range of materials. The DST3 is equipped with a large chamber (300 mm diameter) and three 2” diameter water-cooled cathodes which make it suitable for long-time depositions. The magnetron desk sputter coater is equipped with DC and RF (optional) power supplies. It can sputter semiconductors, dielectrics, and metal (oxidizing & noble) targets.

The DST3 sputter coating system with RF power supply is equipped with auto-adjustable matching box, minimizing the reflected power in the RF sputtering process.

This model contains optional features to increase coated film adhesion to the substrate and improve the film structure, such as a 500 ˚C heater to be installed to heat the substrate during the deposition process, or a 300 V DC bias voltage can be applied to the substrate.

According to state of the cathodes, DST3 is available in two models:

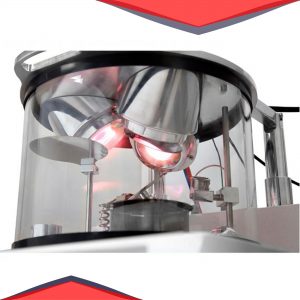

- DST3 – A (Angled Cathodes):

The DST3-A is equipped with three angled cathodes with a common focal point. It can sputter from two or three (Optional) targets simultaneously or independently to form alloys or multilayer deposition respectively.

The maximum size of substrates in this model could be 3 inches.

- DST3 – S (Straight Cathodes):

DST3-S with three straight 2-inch water-cooled cathodes is suitable for sputtering a single large specimen with a diameter up to 20 Cm or several small specimens.

Features

Hardware

- High vacuum level with a built-in turbo pump

- Two-stage rotary vane backing pump (Diaphragm or scroll pump)

- DC and RF (Optional) power supplies suitable for metals, semiconductors, and dielectrics

- Three 2” water-cooled angled, magnetron cathodes suitable for producing alloy films (DST3-A) and multilayer deposition (DST3-A/S)

- Large sample holder stage (8 inches) for DST3-S

- Cathode mask designed for large substrate uniform deposition (DST3-S)

- Two fixed and movable quartz crystal monitoring systems for real-time thickness measurement (1 nm precision)

- Gas injection control through two precision Mass Flow meters (MFC) for fine control of vacuum pressure and Ar flow or reactive sputtering gas

- Full-range vacuum gauge

- Cathode selection motor

- Sample rotation, height, and tilt adjustable (For 3-inch sample holders)

- Three manual or electronic (Optional) shutters

Automation

- Intuitive touch screen to control the coating process and rapid data input

- User-friendly software, updatable via network

- Semi-full automatic Timed or Thickness coating process (Optional)

- Repeatable, programmable sputtering process in the automatic mode

- Adjustable DC/RF deposition parameters through the touch screen panel (Optional)

- Records and plots coating parameters graphs

- Automated target selection

Optional Facilities

- RF power supply and matching box for deposition of conductive and non-conducting targets

- Plasma cleaner

- 300 V DC substrate bias voltage

- 500°C programmable substrate heater with software control

Clean Vacuum

The vacuum chamber is a Cylindrical Pyrex with 300 mm OD and 200 mm H (Adjustable to 250mm H). The DST3 is fitted with an internally mounted turbo molecular pump, backed by a 6m3/h two-stage rotary vane pump (Optional). It introduces a clean vacuum without oil contamination which normally exists with an ordinary diffusion pump.

Touch Screen Control

DST3 is equipped with a 7” colored touch-screen panel using user-friendly software to control and adjust the deposition process data. The vacuum and coating sequence information can be observed as digital data or curves on the touch screen. The last 300 coatings information is saved on the history page.

Sample Holder

The holder is made in two sizes, 3 inches (Available in DST3-A and DST3-S) and 8 inches (Available in DST3-S), but the user can order customized sizes according to their needs. Several S-clamps are created on the small sample holders to hold the small samples with a simple method during the rotation.

Plasma Treatment (Plasma Cleaner Option)

DST3 can be equipped with the plasma cleaner as an option. Plasma treatment/cleaning is the process of removing organic matter from the surface of the substrate or functionalizing it through the use of an ionized gas called plasma. Plasma treatment can modify the wettability of the substrate surface and enhance its hydrophilicity or hydrophobicity for effective subsequent depositions. Also, applying plasma to the substrate before thin film deposition eliminates surface contaminations (C-based oxides) and improves the adhesion between the substrate and the subsequent layers.

Specification

- Turbo molecular pump with different pumping speeds (Optional):

| Pumping Speed | 90 l/s | 250 l/s | 350 l/s |

| Ultimate Pressure | 8 x10-6 Torr | 3 x10-6 Torr | 8 x10-7 Torr |

- Independent sputtering control rate for each cathode to produce fine grain-size structures

- Unlimited deposition time without breaking the vacuum

- Maximum 6 mm target thickness (Including backing plate)

- Automatic control of deposition power independent of pressure

- Automatic safe control of the cathode’s temperatures to protect the lifetime of the magnets

- Electronic throttle valve for 350 l/s turbo pump

- Deposition process curves and data transfer by a USB port to PC

- 0- 1200 V, 0-500 mA DC power supply

- 300 W RF power supply with automatic matching box (Optional)

- Utilities: 220V-110V, 50/60HZ

- Max. consuming power: 3 kW

- Instrument dimensions: 600 W × 800 D × 770 H mm (Without Rack)

- Net weight:160kg (Including pump, rack, and instrument case)

- Two-year warranty

Applications

- Metal, Semiconductor and Dielectric Films

- Nano & Microelectronic

- Solar cell applications

- Co-Sputtering processes

- Glad sputtering

- Optical components coating

- Thin film sensors

- Magnetic thin film devices

- Fine grain structural deposition for SEM & FE-SEM sample preparation

Options and Accessories

- Quartz crystal sensor

- Spare glass chamber

- Sputtering targets

- Sealing gaskets

- 300V DC bias voltage

- Plasma cleaner

- 500˚C substrate heater