The Desk SEM Coater model DSR1 is a compact coating system able to coat noble metals such as gold (Au), palladium (Pd), platinum (Pt) and gold/palladium (Au/Pd) thin films on non-conductive or poorly conductive specimens. Uniform thin films with fine-grain sizes can form in a fast cycle time which makes it an ideal coating system for sample preparation for scanning electron microscopy (SEM) analysis. The Desk Magnetron Sputter Coater (DSR1) is a high productivity tool that delivers consistent and highly repeatable results in the fully automated system. The ergonomic design and small footprint of the DSR1 SEM coating system allows easy use of the system.

The DSR1 is configured as a sputter coater suitable for Scanning Electron Microscope (SEM) sample preparation.

The DSR1 with a 2” magnetron cathode, 80 W switching DC power supply, could be used for research and different thin film applications.

DSR1 can be equipped with a water-cooled cathode which make it suitable for long time deposition.

The maximum size of substrates in this model could be 4 inches.

Features

Hardware

- Two-stage, direct drive rotary vane pump 6m3/h,

- 80 W switching DC power supply

- Quartz crystal thickness monitor with precision of 1nm and resolution of 1 Å

- One 2-inch magnetron cathode

- Electronic gas valves

- Sample rotation, height and tilt adjustable

- Equipped with electronic shutter

- Easy-to-change specimen stages (rotation stage as standard)

- Two-year warranty

- CE conformity

Automation

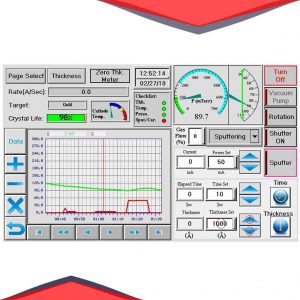

- Intuitive touch screen to control the coating process and rapid data input

- User friendly software, updatable via network

- Controls coating rate to achieve finer grain structures

- Semi-Fully automatic coating process (optional)

- Repeatable, programmable sputtering process in the automatic mode

- Manual or automatic Timed and Thickness deposition

- Able to record and plot coating parameters graphs

- Storing coating recipes for repeatable depositions

Touch Screen Control

DSR1, the desk sputter coater, is equipped with a 7” colored touch screen and full automatic control using a user-friendly software to control and adjust the deposition process data. The vacuum and coating sequence information can be observed as digital data or curves on the touch screen. The last 300 coatings information is saved on the history page and can be transferred to PC by a USB port on the device.

Sample Holders Stages

The DSR1 can be equipped with different sample stage configurations depending on the user requirements. The standard sample stage is rotatable with adjustable height, angel and can be changed easily. The rotary planetary sample stage is a good choice for uniform coating of porous specimens (Optional).

Applications

The DSR1 is a Scanning Electron Microscope (SEM) sample preparation system equipped with a rotary pump to achieve vacuum less than 50 mTorr which is a suitable vacuum range for noble metals sputter coating.

- Noble metal coating for SEM and FE-SEM sample preparation

- Contact coating

- Glow discharge plasma for surface modifications and improved surface hydrophilicity (Optional)

Note: For sputtering of oxidizing metals, please see the DST1 (Turbo-pumped desk sputter coater).

Detailed Features

* Single-phase AC power with appropriate earth connection is required.

Specification

- Suitable for deposition of noble metals

- Able to perform GLAD Sputtering

- Automatic control of the cathode’s temperature to protect the lifetime of the magnets

- Max. power consumption: 1.5 kW

Options and Accessories

- Quartz crystal sensors

- Planetary sample rotation stage

- Spare glass chamber

- Sputtering targets

- Sealing gaskets

- Glow discharge plasma rod