DCT is a turbo-pumped carbon coater that is ideal for FE-SEM, EDS/WDS, TEM, EBSD and thin film applications. This high-vacuum coater offers high quality uniform carbon films with fine grain sizes which are suitable for specimens that require high-resolution and high-quality characterization.

Features

Hardware

- High vacuum level with built-in turbo pump 90 L/s (Leybold)

- Two-stage rotary vane backing pump (Diaphragm or scroll pump)

- 500 W switching DC power supply for carbon fiber deposition

- 2 kW high-current DC power supply for carbon rod deposition (Optional)

- Quartz crystal thickness monitor with precision of 1nm and resolution of 1 Å

- Automatic venting valve

- Sample rotation, height and tilt adjustable

- Planetary sample holder (optional)

- Electronic shutter

- Easy-to-change specimen stages (rotation stage as standard)

- Two-year warranty

- CE conformity

Automation

- Intuitive touch screen to control the coating process and rapid data input

- User friendly software, updatable via network

- Semi-full automatic coating process (optional)

- Repeatable, programmable coating process in the automatic mode

- Pulsed or flash carbon fiber coating modes

- Pulsed or ramped carbon rod coating modes

- Automatic carbon fiber/rod deposition according to the set thickness value

- Records and plots coating parameters graphs

- Storing coating recipes for repeatable depositions

Carbon Rod Evaporation in Turbo Pumped Desk Carbon Coater (Optional)

The Desk high vacuum carbon coater could be equipped with carbon rod head (Optional). For this case an external 0-100A high current power supply should be used instead of the internal high current power supply which is designed for carbon fiber evaporation.

Clean Vacuum

The vacuum chamber is made from Cylindrical Pyrex and Stainless Steel. The DCT is fitted to a 90 L/s turbomolecular pump, that can be backed by a 6 m3/h two stage rotary vane pump (Optionally supplied by the manufacturer), or a scroll or diaphragm pump (Based on the customer choice). It introduces clean vacuum without oil contamination which normally exists with ordinary diffusion pump.

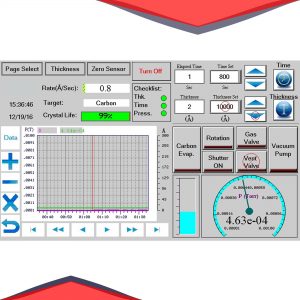

Touch Screen Control of High Vacuum Desk Carbon Coater

Desk carbon coater is equipped with a 7” colored touch screen with full automatic control utilizing a user-friendly software to control and adjust the deposition process data. The vacuum and coating sequence information can be monitored as digital data or curves on the touch screen. The last 300 coatings information is saved on the history page and can be transferred to PC by a USB port on the device.

Sample Holder Stages

The device can be equipped with different sample stage configurations depending on the user requirements. The standard sample stage is rotatable with adjustable height and angle and can be changed easily. The rotary planetary sample stage is a good choice for uniform coating of porous specimens (Optional).

Applications

- Fine grain structural deposition of carbon for SEM, FE-SEM, EDX, and TEM sample preparation

- Conductive layers

- TEM grid plasma treatment for improved hydrophilicity (Optional)

Specification

- Max. consuming power: 2 kW

- Automatically controlled pressure – independent coating

- Fine control of vacuum pressure with automatic leak valve

- Real-time plots of coating parameters

Options and Accessories of Carbon Coater

Desk carbon coater has the following options and accessories:

- Head and power supply for rod carbon rod

- Plasma rod and high voltage power supply for plasma treatment

- Quartz crystal sensor

- Planetary sample rotation

- Spare cylindrical vacuum glass chamber

- Carbon fiber

- Sealing gaskets

Detailed Features